DRY-2017 Semi-automatic pulp environmental protection equipment

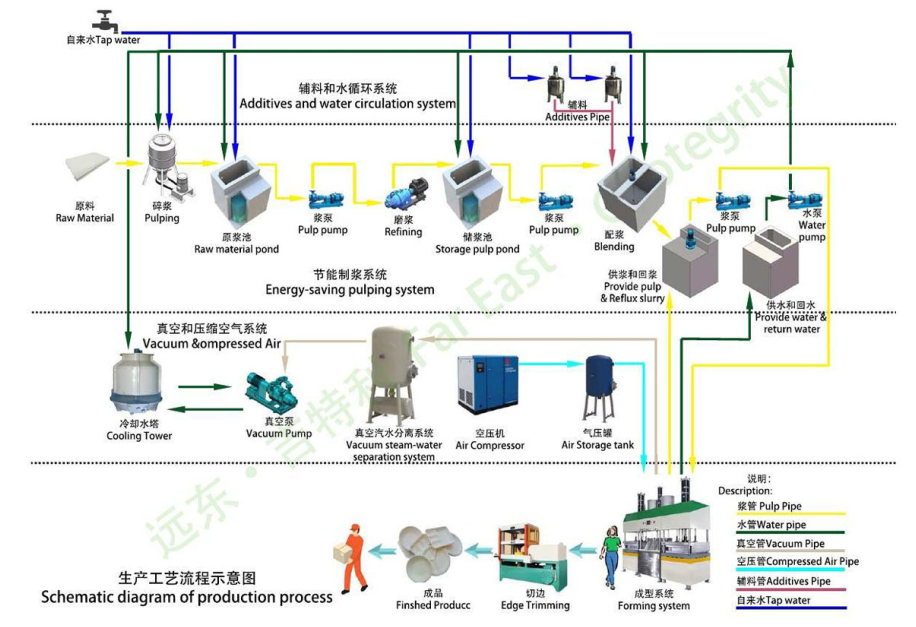

Far East DYR-2017 production line consists of pulp supply system, power system, forming system, inspection and packaging process. The pulp supply system adopts energy-saving high-level gravity technology, which reduces power consumption by 10% and the use of chemical additives. The main engine adopts Siemens motor and German engineering pressure technology

Far East DYR-2017 production line consists of pulp supply system, power system, forming system, inspection and packaging process. The pulp supply system adopts energy-saving high-level gravity technology, which reduces power consumption by 10% and the use of chemical additives. The main engine adopts Siemens motor and German engineering pressure technology

| model | DRY-2017 |

| Capacity | 500~550KG/day |

| working desk | 1050*980mm |

| raw material | vegetable fiber (pulp) |

| Molding type | vacuum suction |

| Mold material | Aluminum alloy 6061 |

| monitor rate | 0.125KW |

| heating mode | Electric heating / heat transfer oil heating |

| circulation time | 55-65S (heating oil heating) |

| manufactures | Disposable pulp environmentally friendly tableware |

1. Simple operation and reliable production output.

2. Pneumatic and hydraulic dual control, energy saving and high efficiency.

3. The mold is of high precision, durable and double cylinder safety device.

yd2481668@126.com

Looking forward your message

Tel

Far East Zhonggan (Xiamen) Technology Group Co., LTD Since 1992, it is the first manufacturer of plant fiber molding tableware machinery in China.

Wechat QR code

WeChat public account

Contact us

Pulp equipment: 0592-7208833

WhatsApp/WeChat: 13960410605 Manager Lin

Ecological tableware: 0595-22412668

WhatsApp/WeChat: 13805944212 Manager Zhang

E-mail: info@fareastintl.com

No. 513 ~ 539 Ji'an Road, Tong'an industrial concentration zone, Xiamen, Fujian Province